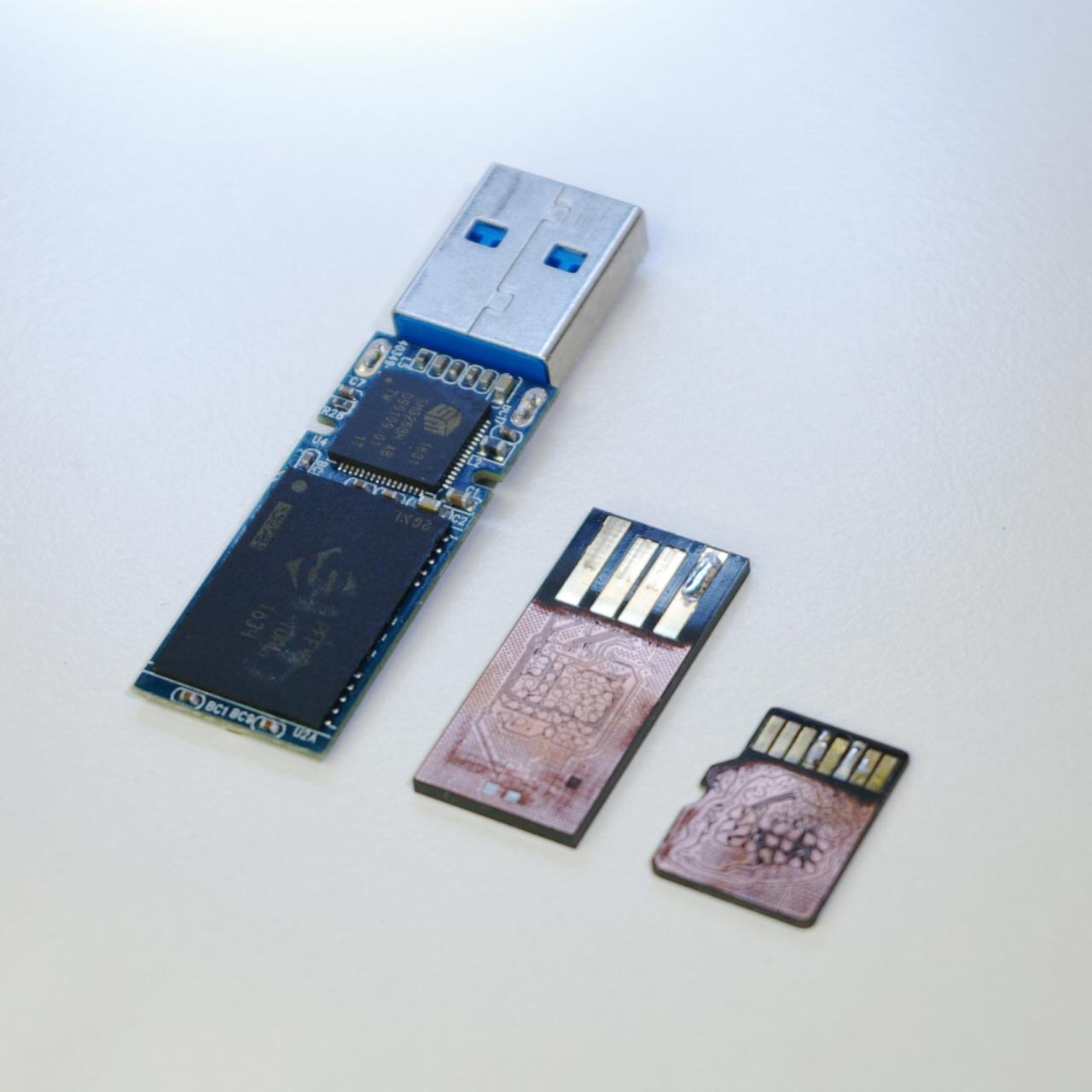

When it comes to flash memory devices – whether USB flash drives or memory cards like SD and MicroSD – there are two main types of construction: surface-mounted technology (SMT) and monolithic. SMT type devices are made of distinct components soldered to a printed circuit board, which requires a certain amount of space to fit all of the components. With monolithic devices, the entire device is manufactured as a single chip (or, in some cases, with a very small number of surface components), which is often small enough to be contained in just the space of a USB connector.

Monolith construction is most often used to reduce the size of the device – small keychain flash drives and super compact memory cards like MicroSD use monolithic construction to fit the very small form factor, but even some full size flash drives and larger memory cards may hide a monolith inside. (Learn more: How to tell if you have a monolith)

When a flash drive dies: SMT vs. monolith

The technical differences between SMT and monolith devices generally won’t affect the average consumer, but a failed monolith poses unique challenges for data recovery.

Most flash drive failures are due to a broken connection or failed component. The USB connector may be damaged, or part of a circuit may fail such as a resistor or capacitor, or in some cases, the microcontroller itself may fail. With an SMT type drive, as long as the NAND chip – the component that stores the data – is intact and functional, it is usually possible to repair broken traces and replace failed components to restore the device to normal function and copy the data. As a last resort, the NAND chip can be removed from the device for direct reading with data recovery tools, but that’s a complex and time consuming process, so repairing the device is preferable whenever possible.

However, with a monolith type device, all of those components are internal, which makes it virtually impossible to repair in most cases. Monolith recoveries are much more likely to require directly reading the NAND than SMT recoveries are. But even that process differs from SMT recovery in a crucial way…

How accessing the NAND differs between discrete chips and monoliths

Most NAND chips used in SMT type drives come in a small handful of form factors, so a data recovery technician can handle the vast majority of chips with only a small number of chip readers. However, with monoliths, the NAND is embedded inside the device. To interface with it, it’s necessary to remove the outer layer of the device (fine sandpaper, a fiberglass pen, or even laser tools can be used) to reveal the copper traces and contacts underneath, and then attach leads or wires to the appropriate contacts to interface with the NAND.

However, there are no industry standard pinouts for monoliths; different devices have different layouts and pinouts. Some data recovery tool developers offer databases of known monolith pinouts, and there are a few relatively more common pinouts that are shared by some devices, but we frequently encounter unique devices that aren’t included in those databases. At that point, a logic analyzer and an in-depth understanding of the signals used by NAND flash are needed to detect and identify the necessary connections and read the chip.

Monolith flash pinout analysis

With a logic analyzer, it is possible to inspect the device’s electrical signals and their waveforms, and by recognizing patterns in their behavior, identify which contacts carry the necessary signals, which in the majority of cases include:

- read enable (RE)

- write enable (WE)

- address latch enable (ALE)

- command latch enable (CLE)

- at least 8 data signals (some devices use 16)

- at least 1 chip enable (CE) signal

- at least 1 ready/busy (R/B) signal

Once those are identified, it’s also necessary to identify the correct order of the data lines. If there are multiple CE and R/B lines, their order must be identified as well. Once the pinout has been identified and the chip is connected properly, a dump of the data can be read, and the recovery process can proceed the same as a traditional chip-off recovery.

Due to the higher complexity of reading failed monolithic flash drives, many data recovery providers don’t work with these devices at all. Blizzard Data Recovery is one of the few data recovery companies in the US with monolith pinout discovery capabilities, allowing us to work with and successfully recover a wider variety of devices.